Blog

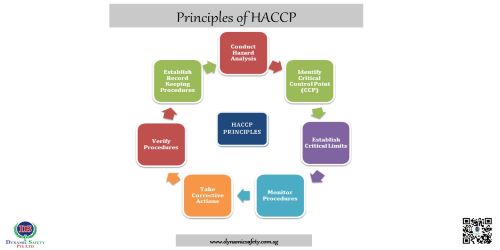

Principles of HACCP

Hazard Analysis is a preventive approach to food safety, which identifies biological, chemical, and physical hazards in the production process that can cause the finished product.

Critical Control Point (CCP)

These points can be applied at stages of the process to reduce the hazards to an acceptable (critical) level.

Critical Limits

The safety limits that determine a maximum and minimum value for each Critical Control Points. It separates the safe product from an unsafe product. Critical limits can be monitored by measurement.

Monitoring

Monitoring procedures include observations or measurements to assess whether the Critical Control Point is being met.

Corrective Action

The corrective actions that need to take if there is any departure from the established critical limit. Corrective actions ensure that the products are not injurious to health.

Verification

This verification is to determine that the food safety management plan is properly implemented and all the hazards were identified.

Record Keeping & Documentation

Record Keeping & Documentation contains complete records & forms with the Food Safety Policy.

Dynamic Safety consultancy experts will help you to give requirements for Hazard Analysis and Critical Control Points system to ensure food safety and increase quality for your company.